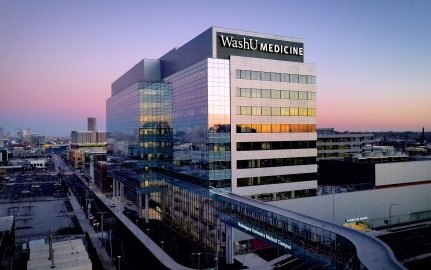

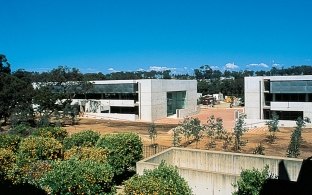

The Salk Institute East Building

La Jolla, CA

“Optimize, don’t compromise,” was the inspiration Dr. Jonas Salk expressed to the project team responsible for constructing a new landmark for scientific research at the world-renowned Salk Institute for Biological studies in La Jolla, Calif. Built on a campus master planned by famed architect Louis I Kahn in the early ‘60s, the Salk Institute for Biological Studies’ East Building stands approximately 125 feet east of the main complex.

Design and construction of the building addition was much like the scientific studies at the Salk Institute itself — a collective effort to discover solutions to complex problems. The predominant feature of this facility is its smooth, stone-like architectural concrete finish that adorns the structure’s exterior frame and interior walls. In context with the existing campus structures, the building’s facade also incorporates mill-finish, stainless-steel detailing and a frameless structural glazing system at the front entrance. All of the materials were chosen for their simplicity and ability to last generations with minimal maintenance.

Forming a new entrance to the Salk Institute campus, the three-level, 116,000-square-foot addition consists of two, mirror-image wings joined by an open-air plaza at the entrance and underground. Each wing contains undifferentiated, contiguous lab space, as well as lab support areas. The basement houses dry-lab functions, while the top level accommodates flexible wet labs and a seven-foot high interstitial space that simplifies maintenance and alterations. Reception, administrative and research offices are located at grade level of each wing, with a special-events lobby, a 300-seat auditorium and meeting rooms housed below.

The Challenge

Much like the legacy of Dr. Salk’s life-changing research, the East Building project was immersed in discovery and innovation.

Constructing any research facility involves scheduling, management and other construction challenges. The complex mechanical, electrical and plumbing systems in research buildings also require the coordination of experienced construction personnel. Yet, these complexities weren’t the primary challenge of The Salk Institute East Building project. The main feat was constructing the facility’s architectural concrete finish.

Dr. Salk’s directive for their new addition was to advance the effort attempted, but not achieved for the concrete work on the original buildings 30 years earlier. Ingenuity, craftsmanship and quality were paramount to achieving his vision. The building team not only had to develop a process for delivering this smooth, stone-like surface in approximately 200,000 square feet of concrete, but also had to implement it consistently throughout the structure, without any patching.

Building-height limitations imposed by the California Coastal Commission and meeting the Institute’s goal for flexible space provided additional project challenges.

The How

From the start of the East Building project, Dr. Salk assumed an active role, directing McCarthy to “experiment” with the concrete mix to create the novel architectural concrete surface. His first visit to McCarthy’s mock-up yard further motivated the craftsmen to achieve this goal.

In order to accomplish Dr. Salk’s vision, McCarthy addressed five concrete-specific issues: mix design, form design and erecting, reinforcing steel, placement and finishing, and stripping and curing. Additionally, the team studied archival information related to the original structures. This research revealed that in order to achieve a smooth and glossy concrete finish, they would need to cast against a smooth, watertight non-absorptive surface.

Several generations of mock-ups were created to develop a suitable surface, choosing polyethylene as a form liner rather than liquid polyurethane, which was used in the existing buildings. The polyethylene was selected for its smooth composition that helped reduce air pockets on the concrete surface and eliminated the need for separating agents. Stronger formwork and changes to the original concrete mix were also developed to give the building’s interior and exterior surfaces a uniform appearance.

Highly flexible lab space was another goal requiring ingenuity. Full-height concrete shear walls were developed along the perimeter of both wings to enhance user flexibility by freeing up lab spaces at any permanent wall. The box-like shear walls simultaneously offer lateral stability in east-west and north-south directions, providing support to the elevators, mechanical rooms and stairs on the perimeter of each level. Demountable stainless-steel window walls on corresponding sections of the facades can easily be removed to facilitate equipment changes in labs and mechanical rooms.

Building-height limitations imposed by the California Coastal Commission created challenges related to the building’s interstitial system and floor-slab design. Requiring nine-foot depths to achieve the stiffness necessary for vibration-free lab space, a long-span interstitial system wasn’t an option. Therefore, columns were added in the labs in order to reduce the depth and span of the interstitial space.

Building-height limitations also prompted variations in the floor-slab design. The team built a stiff-ribbed joist system to support vibration-sensitive labs on the second floor, while a shallower two-way suspended slab was used in administrative areas, where live loads and vibrations are not an issue. The shallow slab also helped increase room for the interstitial space below. A conventional slab on-grade minimizes vibration in the basement and provides the necessary infrastructure to convert support space to labs.

Eliminating construction disruptions to sensitive lab services and research at The Salk Institute also played a key role in the project’s success. An informal partnering process was implemented across the design and construction team to mitigate any disturbances to the Institute’s existing operations. The team effort allowed two totally divergent ways of life — research and construction — to seamlessly coexist and progress productively over the two-year project duration.

The Outcome

The Salk Institute East Building now stands as a modern masterpiece of concrete innovation, earning McCarthy a reputation as a leading innovator in concrete construction. Since the completion of the project, McCarthy has applied many of the techniques first developed on the East Building to other notable concrete project across the nation.

Additionally, The Salk Institute has patented the project’s revolutionary architectural concrete forming technique and is using the profits to produce revenue for scientific research at the Institute.

Collaborating with Dr. Salk was an opportunity the men and women involved in the project will never forget. When he passed away shortly before the East Building’s dedication, the world lost a kindhearted and humble man, as well as one of the world’s greatest scientific minds. Although he did not live to see the new facility in operation, Dr. Salk’s influence on its design and construction will live on in the innovation achieved and in the landmark building created to advance science discovery and human health worldwide.

116,000

SQUARE FEET

200,000

SQUARE FEET CONCRETE

As an edifice, it exceeds our expectations. It is a celebration of an extraordinary vision and of superb craftsmanship.

Trustee Chairman The Salk Institute

Awards and Recognition

American Concrete Institute

American Concrete Institute

San Diego International Chapter

1996 Build America Award

Merit Award Winner

AGC of America1996 Constructor Award

Innovation in Construction Techniques

AGC of California1996 Craftsmanship Honor Award

American Institute of Architects

California Chapter

Anything worth doing is worth doing well, and that was expressed in the spirit and the work that was done here.

CONSTRUCTION MANAGER

Heery International

ARCHITECT

CO Architects (formerly Anshen + Allen)

ENGINEERS

Barrett Consulting Group (civil)

Ove Arup & Partners (structural and mechanical/electrical)

CONSULTANTS

Arup Acoustics (acoustics/vibration)

Carmen Nordsten Igonda Design (interior design)

Debra Nichols Design (signage design)

Earl Walls Associates (laboratory planning)

Kawasaki Theilacker Ueno & Associates (associate landscape architect)

Rabourn Associates (conference center planning)

Sherr & Wagner (landscape architecture)